Oil water separators are essential for petrol stations, construction sites, marine operations, car wash businesses and any other business or location prone to oil contamination.

These systems prevent harmful discharge into stormwater by separating oil, grease, and hydrocarbons from wastewater. Ensuring compliance with environmental legislation throughout Australia, they also play a role in water recycling for businesses looking to reduce mains water usage and any wastewater disposal costs.

From workshops to wash bays, oil water separators are adaptable to a variety of environments and contamination levels. The following breakdown explains how these systems function, the key benefits for your business, and why professional guidance is essential.

How Do Oil Water Separators Work?

Oil separators operate by using gravity and separation technology to remove oil and hydrocarbons from water. The process typically involves the following steps:

- Initial Separation – Wash water enters the oil separator, where heavier solids such as dirt and debris, settle at the bottom.

- Oil Separation – Lighter oils and hydrocarbons float to the surface, while water flows through internal baffles that enhance separation.

- Coalescing Plate Technology (Advanced Systems) – Specialised coalescing plates help small oil droplets merge into larger droplets, making them easier to separate and remove.

- Clean Water Discharge – The treated water is either discharged in compliance with regulations or directed to a recycling system for reuse.

Oil Water Separators Vs. Oil Skimmers

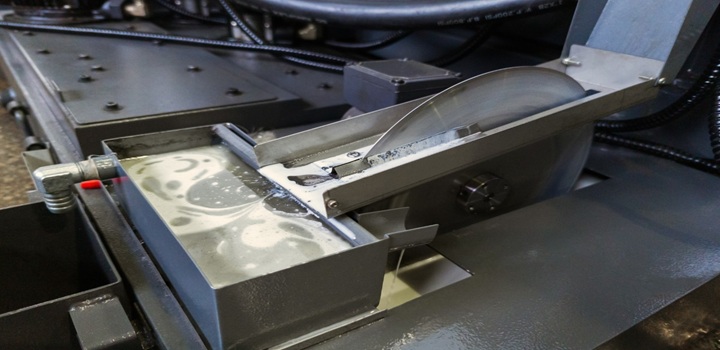

While oil skimmers are often used for removing surface oils from water, they are generally less effective than oil separators in commercial applications. Skimmers work by using belts, disks, or brushes to remove floating oil, but they struggle with emulsified oils and small oil droplets that remain suspended in water.

Key advantages of oil separators over oil skimmers:

- More Comprehensive Treatment: Oil separators can handle free-floating and emulsified oils, whereas skimmers only remove surface oil.

- Better Compliance: Skimmers may not meet stringent wastewater discharge regulations, while separators ensure full compliance.

- Higher Efficiency: Coalescing plate separators significantly improve oil separation, making them more effective for high-volume wash bays.

- Reduced Maintenance: Skimmers require frequent cleaning and adjustment, whereas oil separators operate with minimal maintenance.

Due to their ability to handle both free-floating and emulsified oils, oil water separators are the gold standard in commercial wastewater treatment. As such, if you’re a business or commercial entity seeking a long-term, high-performance solution for wastewater management, this is the option most experts recommend.

(Image: Oil skimmers cannot remove suspended oil. Credit: z1b/Getty Images)

Why Oil Water Separators Are Essential in Commercial Wastewater Management

As noted above, the presence of oil and hydrocarbons in wastewater can lead to severe environmental and operational challenges. Oil water separators are specifically designed to address these risks by providing effective removal of contaminants, ensuring cleaner water discharge and promoting sustainable water reuse practices.

Investing in a quality oil water separator as part of a commercial water treatment system offers several benefits, including:

- Environmental Protection: Prevents oil pollution and protects local water bodies.

- Regulatory Compliance: Meets industry and government wastewater discharge standards.

- Improved Water Recycling: Enhances the efficiency of water treatment and recycling systems.

- Reduced Maintenance Costs: Prevents blockages and damage to wastewater infrastructure.

(Image: Efficient wastewater management. Credit: Armastas/Getty Images)

The Importance Of Investing In Superior Oil Water Separator Solutions

Wherever there are large volumes of water at a high flow rate that contain oil, grease or similar contaminants, measures must be in place to stop these being washed into waterways and remain legally compliant. This is why installation of an oil water separator is an essential requirement for commercial wastewater treatment, whether in wash bays, workshops or industrial sites.

Rather than navigating this independently, ensuring your business invests in a quality oil water separator, tailored to your business needs and installed by an expert is strongly recommended.

Not only will this provide peace of mind that your operations can continue to run smoothly, this also ensures that you are operating sustainably, responsibly and that legal repercussions from non-compliance can be avoided.